100% Quality Control of Resistors with FLIR Thermal Imaging Camera

Cutting down failure rates of electronic components is essential for companies that want to supply a perfect product to their customers. The only way to ensure this is by checking each individual component to provide 100% quality control. This requirement was addressed by Isabellenhütte - a manufacturer of resistance alloys for thermocouples, alloys for extension leads and passive components used in the automotive industry - by using a thermal imaging camera system from FLIR Systems.

Located in Dillenburg, near Frankfurt, Germany. Isabellenhütte's products are used by the automotive industry in fuel injection systems and other electronic control units. The company has a deserved international reputation for the high quality of its products. To achieve and maintain the high quality standards demanded by its customers worldwide, the company invests heavily in quality control and research & development.

Reducing failure rates by 100% control

But despite these investments, customers were still reporting failure rates of up to 5 p.p.m. By Isabellenhütte's exacting standards, even a failure rate of 10-8 was considered unacceptable. It therefore decided to implement 100% control of all components. Weak points in the components may occur during the manufacturing process, and these can later result in faulty built-in electronic devices. The result is that the final electronic systems will not achieve the designed durability, leading to potential quality problems for both the device supplier and the automotive company.

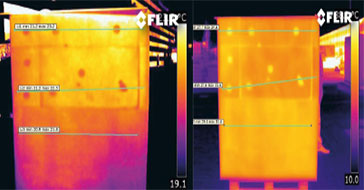

The solution that Isabellenhütte adopted was to install a thermal imaging camera system from FLIR Systems. This is used to inspect each component produced. Within a timeframe of less than 1 second, the system makes an infrared image that allows it to check the resistor for possible defects. These are shown as hot spots in the image, resulting from the higher surface temperature of a faulty device.

In the quality control process, each resistor is charged for a very short period of time. Within 20 ms the thermal imaging camera observes the thermal cycle of the component. Using the machine vision software IRCheck designed by the system integrator

Automation Technology

(www.automationtechnology.de), the computer compares the maximum detected temperature with the average surface temperature of the resistor. If the difference between the maximum and average values exceeds a predefined value, this means that the component has a hot spot. When a hot spot is detected a trigger signal is automatically generated to remove the faulty component from the production line. The whole process takes less than 1 second, from the entry to the exit of the testing machine. The thermal image with the defective area on the component is stored in a database for statistical process control purposes.

Even higher quality standards

"Infrared thermography, and in particular the FLIR Systems thermal imaging camera, proved to be the perfect way to ensure that our quality standards are even higher than before", says Mr. Eichman, Production Manager at Isabellenhütte. "We now monitor our production 24 hours a day. As we no longer need an operator to do this, we are saving money. Our initial investment in the thermal imaging camera repaid itself within an extremely short period of time. What is more important each and every resistor is now checked, allowing us to deliver a perfect product to our customers."

It goes without saying that Isabellenhütte's efforts to supply a perfect product are highly appreciated by their demanding customers, ensuring that they remain a

leading company in their sector.

Infrared quality control principle:

- Each resistor is electrically charged for an extremely short period of time

- A 20 ms snapshot is taken with the FLIR Systems thermal imaging camera

- The difference between the maximum and average surface temperatures of the component is compared against a predefined value

- If a faulty component is detected, a trigger output is automatically generated to remove the component from the production line

- The corresponding thermal image is stored in a database for statistical quality control purposes

System configuration:

- FLIR thermal imaging camera with a digital high-speed interface and an acquisition rate of 50 frames/s

- Close-up lens 34/80 with a 34 mm horizontal field of view (HFOV) and 80 mm focal length

- Industrial components such as armoured cables, 19" rack and computer running Windows® NT™

Key benefits for the customer:

- Fully automated quality control

- 24-hour operation with no need for an operator

- 100% quality control of every component

- Greatly reduced rate of later system failures

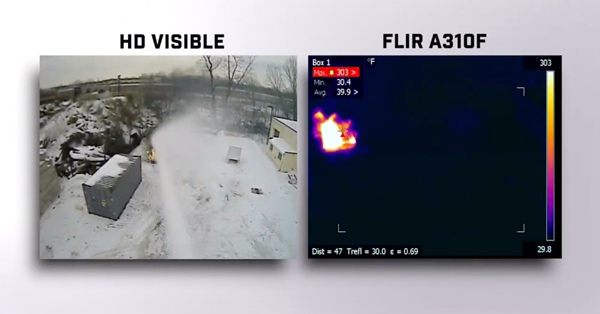

FLIR A310

The thermal imaging camera used for this application is the ThermoVisionTM A320M. This model has been replaced by the even better performing FLIR A310

The FLIR A310 is a compact fixed mounted camera that can be installed almost anywhere. It can measure temperature differences as small as 0.05 ºC. Exclusive measurement analysis function and alarm functions make the FLIR A310 the perfect tool for many applications.